MIL-DTL-18714F (OS)

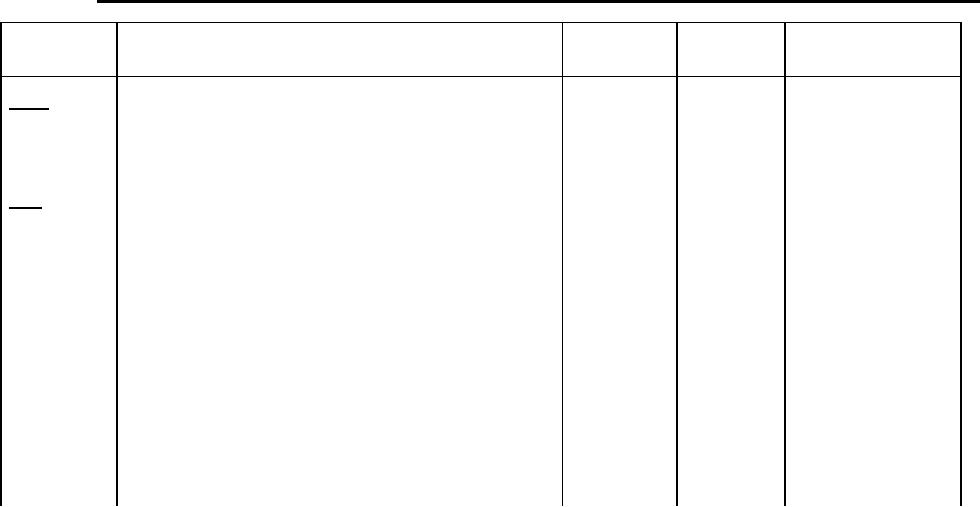

TABLE XI. Conformance inspection by classification of characteristics for ignition cup and electrode assembly, drawing number 2434751

Conformance

Requirement

Inspection Method

Classification

Examination or Test

Criteria

Paragraph

Reference

Critical

AIE

C1

Note 6: There shall be a continuous fillet of the colored epoxy to the

100%

3.2 & 3.10

interface of the ignition cup insulator and the inner lip of the ignition cup as

shown. The fillet shall be fully cured (rigid) and not tacky. It shall be

continuous with no holes, cracks or breaks.

Major

AIE

M101

Note 3: A five pound min dead weight force applied to the (.100) electrode

3.2

Level IV

diameter [shall not unseat the electrode and electrode insulator, find no. 3,

from the ignition cup and the ignition cup insulator].

M102

Note 4: The electrode insulator shall not protrude forward of -B-.

AIE

3.2

Level IV

M103

Note 5: The assembly shall be thoroughly clean and dry prior to application

AIE

3.2 & 3.10

of epoxy.

Level IV

M104

Note 7: After curing, the volume of cavity shall be a minimum of 34

AIE or NSIG

3.2

microliters.

Level IV

M105

Note 8: No epoxy shall be present on other external surfaces.

AIE

3.2 & 3.10

Level IV

M106

Note 10: The insulation resistance between the electrode and ignition cup

AIE

3.2, 3.5 & 3.6

shall be 50 megaohms min with 500 VDC min.

Level IV

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business