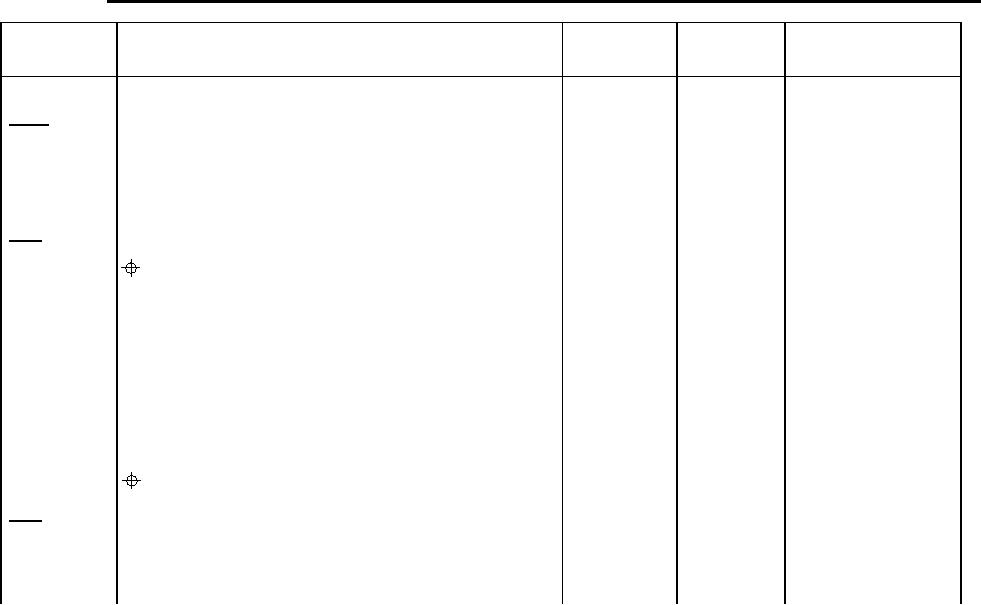

MIL-DTL-18714F (OS)

TABLE XXI. Conformance inspection by classification of characteristics for primer tube, drawing number 685475 and MIL-DTL-15119A

Conformance

Requirement

Inspection Method

Classification

Examination or Test

Criteria

Paragraph

Reference

Drawing 685475

Critical

C1

Note 3: Hydrostatic test to 18,000 psi min, 19,000 psi max

-C2

.750-32UN-2A -A-

100%

3.2

AIE

C3

32 holes

100%

3.2

AIE

C4

Ø .5990 +.0000

100%

3.2

AIE

Also, see C1 in MIL-DTL-15119, the specification for steel tubing

100%

3.2

AIE

Major

M101

Ø .218 ± .010

M102

[Ø .020(M)][C(M)][B]

Level IV

3.2

AIE

M103

Ø .580 +.000/-.010

Level IV

3.2

AIE

M104

.830 max runout

Level IV

3.2

AIE

Level IV

3.2

AIE

M105

Note 4: Zinc plate IAW ASTM B633, SC 1, type II, maximum thickness of

20μm. Threads are not subject to minimum thickness requirement, but

Level IV

3.2

COA (for thickness)/AIE

shall show evidence of coating.

M106

Ø .760 +.010/-.000

M107

.740 min full thread

Level IV

3.2

AIE

M108

8.250 ± .020

Level IV

3.2

AIE

-M109

Ø .5990 -.0007

Level IV

3.2

AIE

+M110

.750-32UN-2A

Level IV

3.2

AIE

M111

[Ø .003(S)][A(M)]

Level IV

3.2

AIE

Level IV

3.2

AIE

Minor

Note 2: Finish as drawn, surface texture √ 125 for machined surfaces

201

Level II

3.2

COC

202

Note 3: Material, see MIL-DTL-15119 requirements; contains critical and

major characteristics

Level II

3.2

AIE

34

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business